How Much Heat Is Lost Through Windows

• A typical house loses 10% of its estrus through the windows.

• The successful specification of energy efficient windows requires a audio agreement of the dynamics of thermal performance.

• Overall free energy balance = solar estrus gain – heat loss

Heat loss

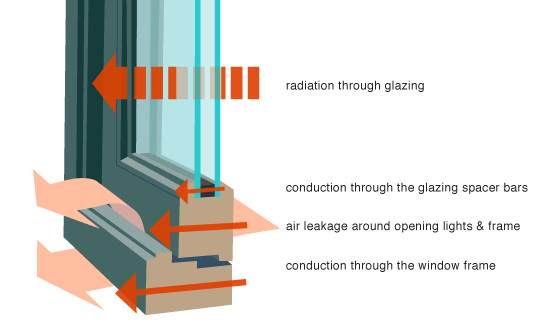

Windows lose heat in a number of ways:

• Around 2/3 of the free energy lost from a standard window is through radiation through the glazing. The within pane of a double-glazed unit absorbs rut from the room and transmits it through conduction and convection (see below) to the cooler outside pane, and then to the outside. The thermal transmittance of a glazing unit of measurement, known equally the U-value, is expressed in units of Watts per foursquare metre per degree of temperature difference (W/1000twoC)

• A small corporeality of estrus is lost through convection within the glazing cavity. In some circumstances, particularly in wider glazing cavities, air inside the crenel is warmed by the inner pane. The warm air rises and is replaced by libation air and so sets upwardly a convection electric current which transfers estrus from the inner pane through to the outer pane(s). Convection up to 20mm in double-glazing units particularly with argon gas, which is denser than air, is insignificant; In triple glazing there is an improved performance up to betwixt xviii-20mm.

• Heat is conducted through the window frame. The rate of conduction (U-value) is governed past the frame material – in general, timber frames perform better than metal in this respect.

• The panes in double glazing are separated and sealed at their perimeter by spacer bars. Usually fabricated from aluminium, they represent a small only not insignificant conduction road.

• Later radiations, air leakage is probably the biggest contributor to heat loss from existing windows, particularly in older or badly installed windows. In an era when small gaps in the fabric were relied on equally a form of background ventilation, air leakage wasn't recognised as being the issue that it has go today. Fixed windows lose less heat and larger windows tend to leak less air per unit of measurement area.

The kind of opening method also determines air leakage – traditional sash windows perform the worst whereas elementary casements are generally ameliorate. Leakage is also common around the frame. A combination of pre-fabricated frames and ill prepared wall openings on site have led to a meaning number of badly fitted windows with gaps left over (ofttimes big enough to be filled with newspaper).

Oestrus gain

Though the full general residuum in the UK is for windows to lose heat, they also, to a varying degree blot oestrus and in some instances of high operation windows, there can be a net gain.

Rut is captivated through glazing in two ways:

• Solar gain directly transmitted (chief transmittance) through the glazing and

• Energy absorbed by the glazing and after transferred inwards past convection and radiation (secondary transmittance).

Factors effecting heat proceeds

Glazing technology and the 'Thousand-Value'

The 'M-Value' measures the degree to which glazing blocks oestrus from sunlight. The G-value is the fraction of the estrus from the lord's day that enters through a window. G-value is expressed as a number between 0 and 1. The lower a glazing'south M-value, the less solar heat it transmits.

A window'due south G-value is adamant by the type of glass, or combination of types, that make up the glazing unit of measurement. (come across glazing types below)

In most domestic situations the specification of glazing concentrates on admitting solar energy whilst preventing free energy from being re-radiated from inside.

(The US equivalent of 'Grand-value' is the Solar Heat Gain Coefficient – it differs from the European Chiliad-value in using a different value for air mass)

Orientation

In the UK solar energy is gained through southerly facing windows. Height absorption for windows facing directly to the south will exist during the summer months; Too E and West facing windows will experience maximum heat gain in the mornings and afternoons respectively during the summertime.

Shading

Shading the window areas during the summer months is normally desirable. Whilst relatively easy to achieve with south facing glazing, the lower angle of the lord's day makes eastward and w facing windows more problematic. In these instances, shading might exist possible using part of the building fabric (eg eaves or proprietary shading devices) but an alternative might be to look at the potential of landscape features such as trees.

Measuring window performance

U-values

| The traditional method of measuring a window's functioning is through its U-value. In practice this tin can often be confusing since in that location are 3 types of u-value that can be quoted: • The u-value measured through the centre of a glazing unit alone – 'eye-pane' • The u-value of the window frame solitary. • The overall u-value of the window including glazing unit and frame. – 'overall' (Notation: it is common for window manufacturers to promote the 'centre-pane' u-value of a window rather than the more realistic 'overall' u-value.) |

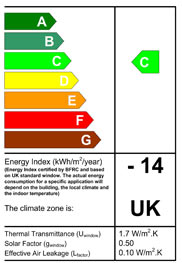

BFRC Rating organisation

| The u-value method of measuring a window'due south performance has proven to been something of a blunt tool, ignoring, equally it does, other factors such as a window'southward chapters to transmit solar free energy. This crudeness of measurement has led, in the last few years, to a system developed by the British Fenestration Rating Quango (www.bfrc.org) that takes into business relationship the multiplicity of factors determining a windows performance and rates on the ground of a nominal free energy remainder from A-M. Most importantly for the window specifier, it encourages manufacturers to publish verifiable data on Ux, g-value and air permeability. Though u-values are all the same often quoted, the BFRC rating arrangement is gaining popularity through its citing by the Edifice Regulations in England and Wales |

Passivhaus certification

Another useful standard gaining basis is that provided by certification past the Passivhaus Institute. The very high standard requires windows to be triple glazed and reach u-values of at least 0.8 Westward/m2C for both the glazing and the frame.

Window technologies

Glazing

'Low-E' Glass

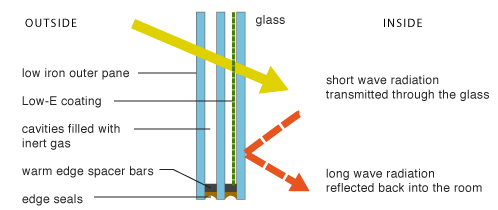

• The most significant development influencing the market has been that of 'Depression-East' glass. By coating the confront of the inner pane of glass with metallic or metallic oxide, brusque wave radiation from the dominicus is permitted to enter the edifice, whilst long wave radiations in the form of heat from the inside is reflected back into the room.

• In summer the coatings tin contribute to the take a chance of over heating by slightly reducing the amount of short wave radiation transmitted through the glass.

• Because of the restricting upshot of the coating, Depression-Glass will always reduce the glazing's Grand-value.

At that place are ii types of Low-E coatings: hard and soft. The deviation between them is their method of application, their transmittance and their durability.

Hard (eg Pilkington K glass): applied during the manufacturing process. Emissivity between 0.fifteen and 2.0

Soft (eg St Gobain Planitherm Total) : practical after manufacture. Emissivity between 0.05 and 0.x. They produce a lower u value. Soft coatings tend to degrade when exposed to air and moisture, are easily damaged, and have a express shelf life.

Gas filled units

Filling the gap betwixt the drinking glass panes with low conductivity gas such as argon or krypton (too every bit the more than expensive xeon) at atmospheric pressure improves the window performance past reducing conductive and convective heat transfer. They are generally used in conjunction with low-emissivity coatings. 1 drawback though might be the long-term integrity of the make full.

Insulating spacer bars

Multiple glazing units are spaced and sealed by spacer bars around the perimeter of the unit. The traditional fabric for a spacer bar is aluminium. But every bit window standards have become more stringent, the rut lost from thermal bridging through the metal has become more than significant. Stainless steel spacer confined are an comeback, but better performance is to exist had through the utilise of non-metal materials such as steel reinforced polymer, glass fibre or structural cream with, typically, a polysulphide seal. This technology is often referred to equally 'warm edge'.

• In highly insulated houses, even with warm edge spacers, at that place will be condensation at the bottom edge of the pane with double glazing. This is because of convection causing colder argon adjacent to the outer pane sinking to the bottom of the unit (In poorly insulated buildings condensation will be at other points). Triple glazing eliminates this problem because of the two cavities.

Depression iron glass

Removing the iron content from drinking glass increases its low-cal transmittance and therefore its solar gain. Low atomic number 26 glass is unremarkably used in the outer pane of multiple-pane units, low-e glass being used for the inner pane.

Frame design and materials

• Although the window specifier might be handicapped past planning restrictions covering the materials and advent of replacement windows, window frames must be considered as an of import area when considering heat loss.

• Most energy lost through a frame is through conduction. Technological developments have been dedicated to reducing the overall conductivity through improved materials and the combination of materials to produce 'blended frames'.

• From a 'light-green' designers indicate of view, the nearly important base material is timber. Hardwood frames are preferable and products are bachelor that see the stringent standards ready by the Passivhaus standard. An culling is to use treated softwood or a forest / aluminium blended where the metal is used on the external face up of the frame – thus significantly improving durability.

• Metal windows have improved through the evolution of increasingly circuitous sections, the more recent of which comprise thermal breaks.

Windows and the BRE 'Light-green Guide to Specification'

The Greenish Guide's approach to rating windows is perplexing to many specifiers. Though the guide is correct in identifying the primacy of performance over the environmental impact of the materials involved, questions keep to exist asked about the veracity of the data that supports PVC windows receiving an 'A' rating (on par with softwood), whilst the arguably more sustainable aluminium / softwood composite windows are awarded a lowly 'D'.

Glazing and comfort

• 1 of the underlying principles of the Passivhaus standard is that of providing 'thermal comfort' to a building'south occupants (for more than information about the concept of thermal condolement encounter world wide web.passivhaustagung.de/Passive_House_E/comfort_passive_house.htm).

• Comfort criteria dictate that the in that location should not be more than than 4 M between any surface and air temperature. Outside of this margin, extra estrus is needed to compensate for the increased feeling of discomfort.

• In a building where the walls are well-insulated the temperature difference between the wall surface and room temperature is minimal, but the temperature differences between glazing and room temperature (assuming an indoor room temperature of 21 K) tin be significant according to glazing type:

- between single glazing and air temperature can be around 20 deg C

- betwixt double glazing and air temperature will be around 8 deg C

- betwixt triple glazing and air temperature will be around 4 deg C (ie within the comfort zone)

Installation

• Windows should be factory-glazed to avert performance loss associated with site installation.

• Gaps betwixt the frame and the wall should be sealed with low expanding foam backed-up with a single-sided, pre-folded loftier-performance agglutinative record (Pro Clima or similar) to provide an airtight bond between the window frame and the wall / vapour control layer.

• Ensure that Low-E glazing is installed the correct way around (check the label)

• Check any requirements for safety glazing.

Further information

• British Woodworking Federation

• FENSA

• Glass and Glazing Federation

• Council for Aluminium in Building

• British Fenestration Rating Council

Window products on GreenSpec

Window products on GreenSpec

Disclaimer

GreenSpec accepts no responsibility or liability for whatever damages or costs of any type arising out of or in whatever fashion connected with your utilize of this web site. Data and data is provided for data purposes merely, and is not intended for trading purposes. Neither GreenSpec nor any of its partners shall exist liable for any errors in the content, or for any deportment taken in reliance thereon.

Source: http://www.greenspec.co.uk/building-design/windows/

Posted by: shannontherfull00.blogspot.com

0 Response to "How Much Heat Is Lost Through Windows"

Post a Comment